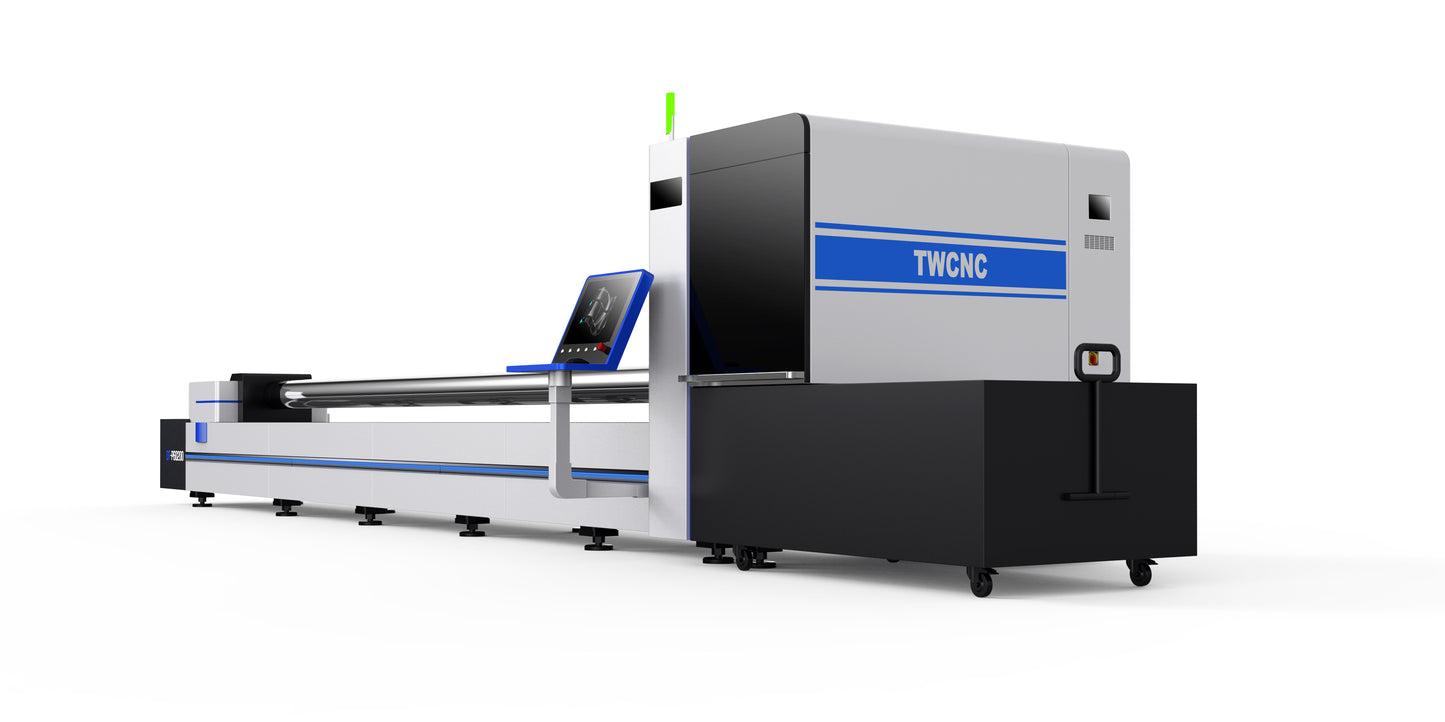

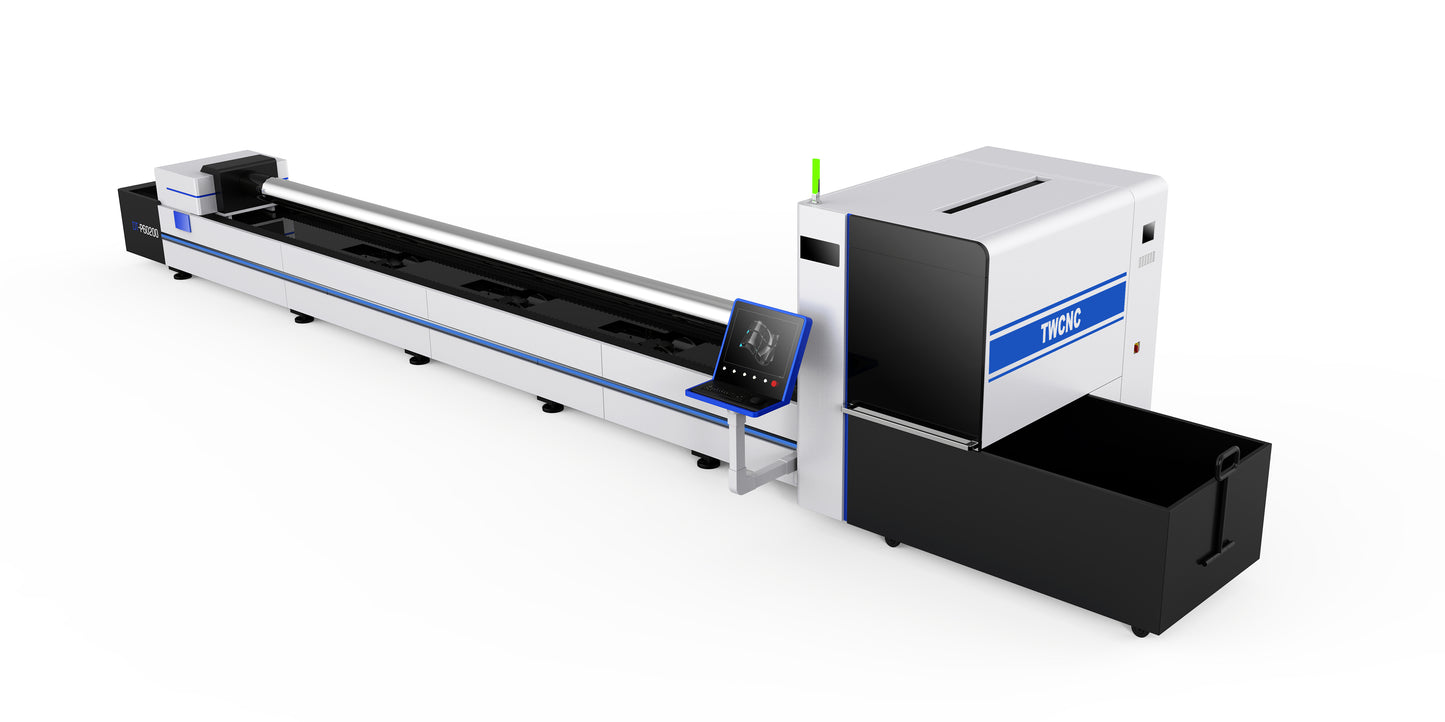

P series laser cutting machine for fully automatic pipe cutting

P series laser cutting machine for fully automatic pipe cutting

(1000w,1500w,2000w,3000w,4000w,6000w,8000w,10000w,12000w,15000w)/1kw,1.5kw,2kw,3kw,4kw,6kw,8kw,10kw,12kw,15kw

2.The Laser cutting equipment has all functions as a professional CNC pipe laser tube laser cutting machine but with economic price.

3.Patented fast full automatic loading and automatic unloading system and working stations.

4.High efficient processing of H beam,C beam,Round Pipe, Rectangular tube, Square tube, Oval tube, Triangle pipe, D shape pipe ,Profile cutting and many other shapes of metal tubes and pipes.

5.Even L steel, Angle steel,Channel steel, I-steel,H-steel,H beam,Special shaped steel also can be processed with high preicision perfectly .

6.The integration of leading-brand components assures you of top performance and high reliability.

7.Stainless steel tube, Aluminum alloy steel,carbon steel pipe, aluminum tube,brass pipe ,copper tube,galvanized steel tube CNC Fiber Laser Cutter.

|

1

|

Product Name

|

CNC Fiber Laser Cutting Machine

|

|

2

|

Product Model

|

TW-6000P

|

|

3

|

Cutting Size

|

3M/6M/9M

Other size can be customized |

|

4

|

Power

|

1000W 2000W 3000W 4000W 6000W

8000W 10000W 12000W 20000W |

|

5

|

Laser Wavelength

|

1,070-1,080nm

|

|

6

|

Max Moving Speed

|

120m/min

|

|

7

|

Position Accuracy

|

0.01mm/m

|

|

8

|

Repeatability Accuracy

|

0.01mm

|

|

9

|

Fiber Laser Source

|

MAX / RAYCUS / IPG / RECI

|

|

10

|

Motor&Drivers Brand

|

Japan Fuji; Japan Yaskawa ; Taiwan Delta

|

|

11

|

Cutting Head

|

Raytools / Au3tech / FSCUT / Ospri / WSX / PRECITEC

|

|

12

|

Control System

|

FSCUT / Au3Tech / Raytools / Weihong

|

|

13

|

Ruducer

|

Japan Shimpo / France MOTOVARIO / Germany Lead-motion

|

|

14

|

Compatible Software

|

CorelDraw/AutoCAD/Photoshop/AI

|

|

15

|

Support Graphic Format

|

LXD/.DXF/.PLT/.AI/.Gerber/.DWG

|

|

16

|

Interface

|

USB,RJ45

|

|

17

|

Gear Rack

|

Taiwan YYC

|

|

18

|

Electrical components

|

Schneider made in France

|

|

19

|

Water Chiller

|

S&A / Hanli / Tongfei

|

|

20

|

Optional

|

Semi-automatic loading and unloading, fully automatic loading and unloading

|

|

21

|

Processing Material

|

Stainless Steel / Carbon Stee l/ Galvanized steel / Aluminum / Copper/ Iron, etc

|

Share

We provide customers with the following services

MAIN AFTER-SALES SERVICE :

All our laser equipment is provided with 24 months warranty. We TWCNC offers free maintenance or replacement service if something is wrong with the equipment under warranty. If it is out of warranty,We TWCNC will send engineers to your factory as soon as possible and only charge the cost of parts.

Installation and debugging & Training

Technicians can be sent to the factory for training (free of service fee for the first time). Customers only need to provide accommodation for engineers.

Free of charge for training within warranty. But customers need to take charge of the cost for accommodation, air tickets, visa fee.

24H online service

TWCNC promises to provide 7×24 hours service after signing the contract. Respond within 1 hour after receiving the notification, provide solutions within 8 hours for general faults, and provide solutions for complex problems within 24 hours.

Remote diagnosis

We TWCNC can check the running status of the customer's laser cutter through our remote maintenance system. Our technicians can perform troubleshooting via remote access instead of on-site diagnosis and maintenance, saving you a lot of time.

Subscribe to our emails

Be the first to know about new collections and exclusive offers.